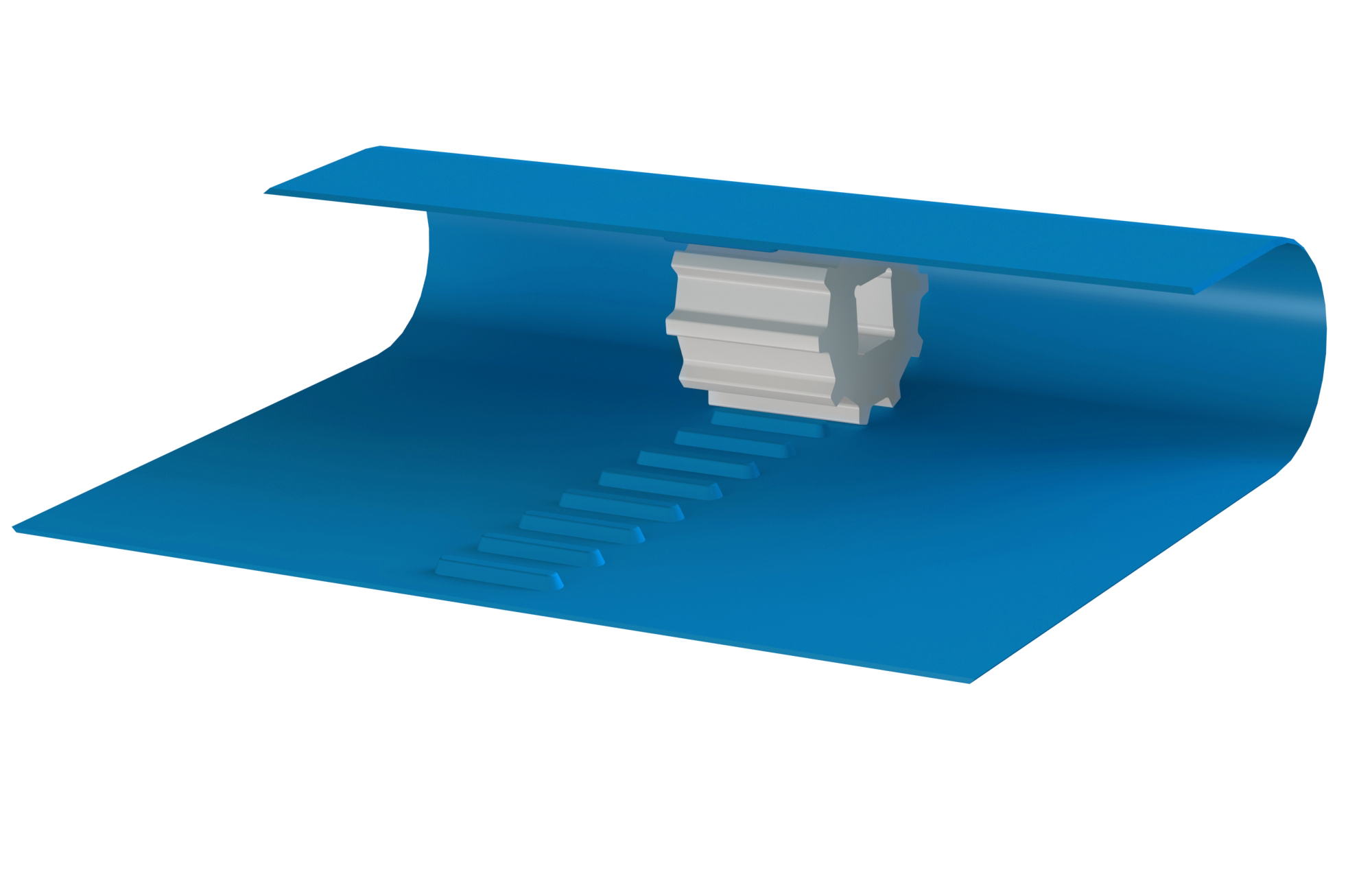

The TPU-X2 Twin/Lock Fastener is engineered to meet the strict demands for food safety compliance.

Its streamlined profile prevents debris buildup and allows thorough cleaning without removal.

Its hygienic design and speed of installation and removal keep downtimes minimal.

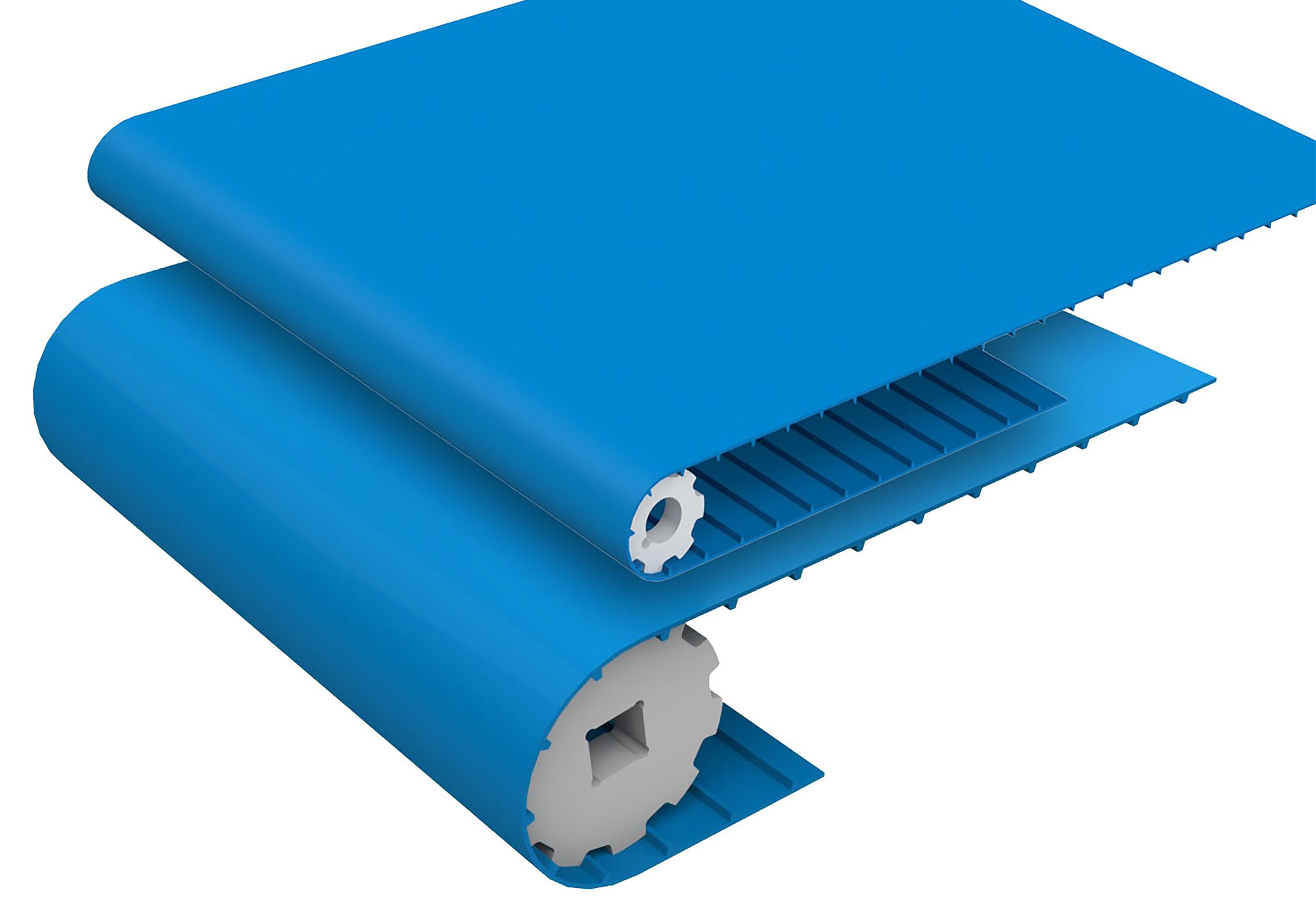

Positively driven Polyflex Drive can be implemented in place of modular belting.

The smooth surfaces of 30S-PD50 allow for simple, efficient cleaning. It provides optimum food safety and reduces cleaning times and detergent consumption in addition to a totally silent operation.

Manufactured with 100% polyurethane or polyester resins, Polyflex Drive meets the most stringent hygiene standards of the food industry.

Characteristics

- Hygienic, homogeneous construction with fully molded teeth and no cords decreases bacteria contamination

- Easy-to-clean construction decreases water and detergent consumption by up to 70%

- Excellent cut & abrasion resistance and excellent resistance to solvents, oils, and greases

- 2” & 1” pitch PD deep tooth design eliminates slippage and provide optimum sprocket engagement for maximum drive

- PDC’s center lugs ensure positive tracking and maximum hygiene due to the added open area

- Zero-tension belt system reduces stress on conveyor components and increases belt and conveyor life

- Easy, fast butt splice minimizes downtime

- Durable HDPE sprockets and accessories are available in a range of sizes

- Easily retrofitted on modular belting applications

Industries Served

- Poultry and Meat Packing

- Fish Processing

- Cheese Processing

- Fruit and Vegetable Processing

- Confectionary Products

- Bakery Industry

- Cereal Processing

- Pharmaceuticals

Documents

- Polyflex Drive Brochure

- PD Sync Brochure

- Polyflex TPU-X2 Brochure

- USDA Meat Poultry Certificate - 3OS-PD50

- USDA Dairy Certificate - 3OS-PD50

- USDA Meat Poultry Certificate - 28S-PD25

- USDA Dairy Certificate - 28S-PD25

- White Paper - 30S-PD50 vs. Modular

To view documents download a free copy Adobe Acrobat Reader.

To view documents download a free copy Adobe Acrobat Reader.